Camping Made Simple

Enjoy flexibility with its free-standing dome structure - relocate easily for the perfect views even after pitching.

| frequency | occasional |

| weather conditions | warm weather |

| rain | heavy rain |

| wind | light wind |

| number of persons | 2 persons |

| assembly type | assembly with poles |

| number of rooms | 1 room |

| storage space | without storage space |

| living area | without living area |

| shape of the tent | dome |

| number of season(s) | 2 seasons |

| weight (in kg) | 3 kg |

| weight of the tent | 2 kg < weight < 3 kg |

| freestanding tent | freestanding tent |

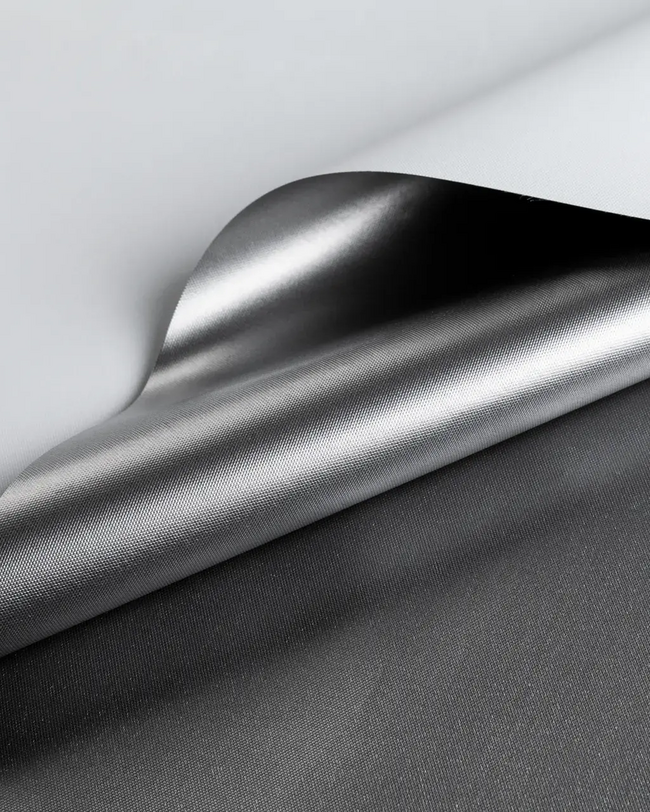

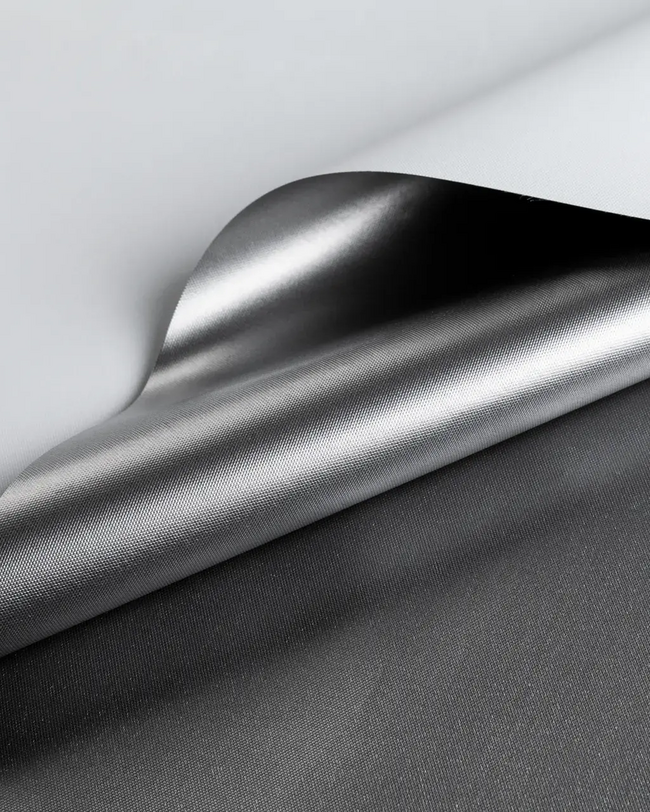

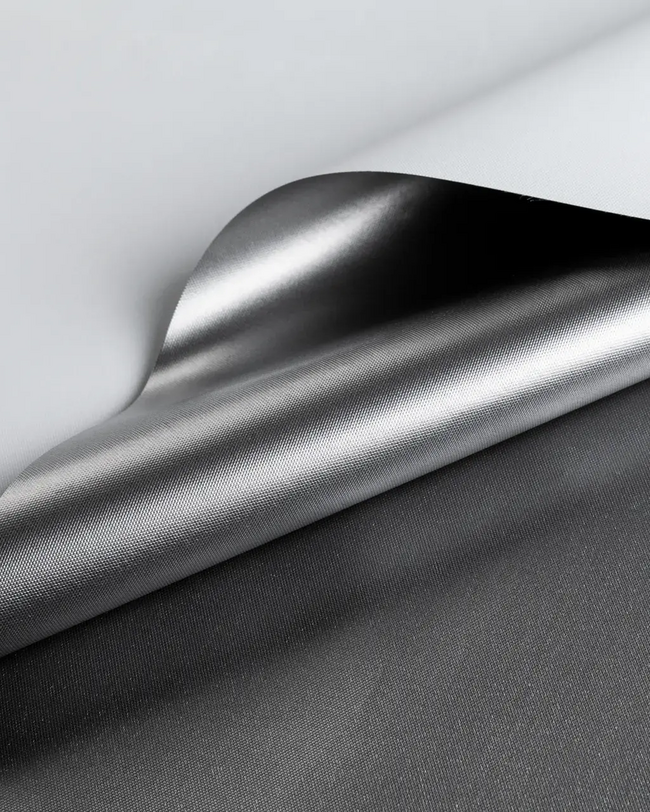

| tent technology | fresh and black |

| type of poles | fiberglass |

| double roof material | polyester |

Pole: 100.0% Glass Fiber |

Inside room: 45.0% Polyester, 55.0% Polyethylene |

Double roof: 100.0% Polyester |

Carry bag: 100.0% Polyester |

We rigorously test QUECHUA products at our design centre at the foot of Mont-Blanc and then in the field under real-world conditions.

Waterproofing test

Our initial lab test simulates a tropical storm with the equivalent of 200mm of rain per hour. The second test is done in the field under real-life conditions by our teams. We use a closed circuit so we can recycle the water.

Wind resistance test

Using a wind tunnel and turntable, we expose each side of the tent to the same wind intensity. Properly pitched, this tent remains habitable to Force 5 winds, measured at 40 km/hr.

Heat and light test

Our Fresh & Black technology is tested for heat and light resistance. The fabric guarantees reduced heat and 99% darkness on the inside.

Sleeping width: max. 65 cm per person.

Storage: after use or cleaning, wait until the tent is perfectly dry before putting it away in order to avoid bad smells and mould.

Do not wash.

Do not dry clean.

Do not iron.

Do not tumble dry.

Bleaching excluded.

Using this mass-dyeing process enables us to reduce CO2 emissions linked to the production of dyed textiles by at least 46% compared to conventional dyeing.

Using this dyeing process enables us to reduce the CO2 emissions linked to the production of the dyed component by at least 60% compared to conventional dyeing.

Using this finishing process enables us to reduce CO2 emissions linked to the production of undyed textiles by at least 58% compared to conventional dyeing.

Using this dyeing process enables us to reduce the CO2 emissions linked to the production of the dyed component by at least 60% compared to conventional dyeing.

Using this mass-dyeing process enables us to reduce CO2 emissions linked to the production of dyed textiles by at least 46% compared to conventional dyeing.

Using this finishing process enables us to reduce CO2 emissions linked to the production of undyed textiles by at least 58% compared to conventional dyeing.

Camping Made Simple

Enjoy flexibility with its free-standing dome structure - relocate easily for the perfect views even after pitching.

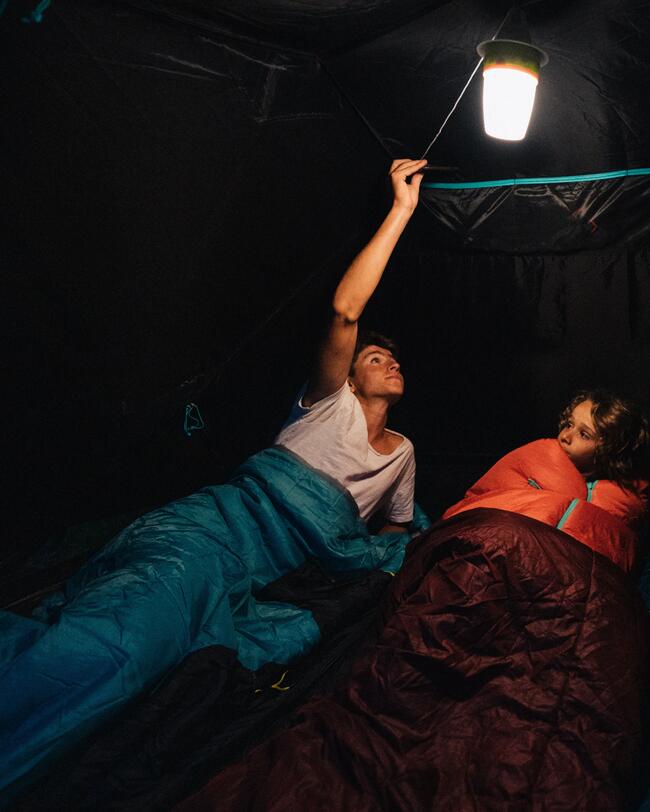

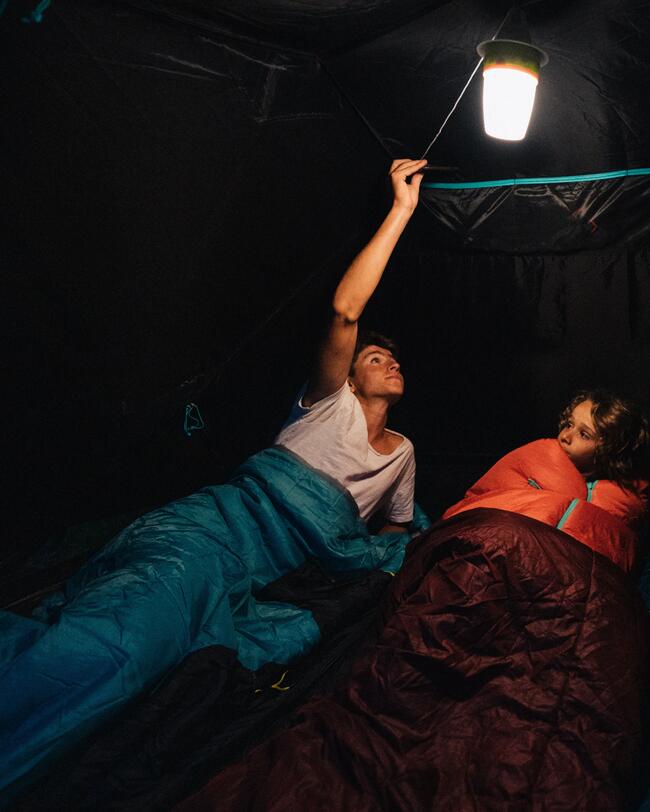

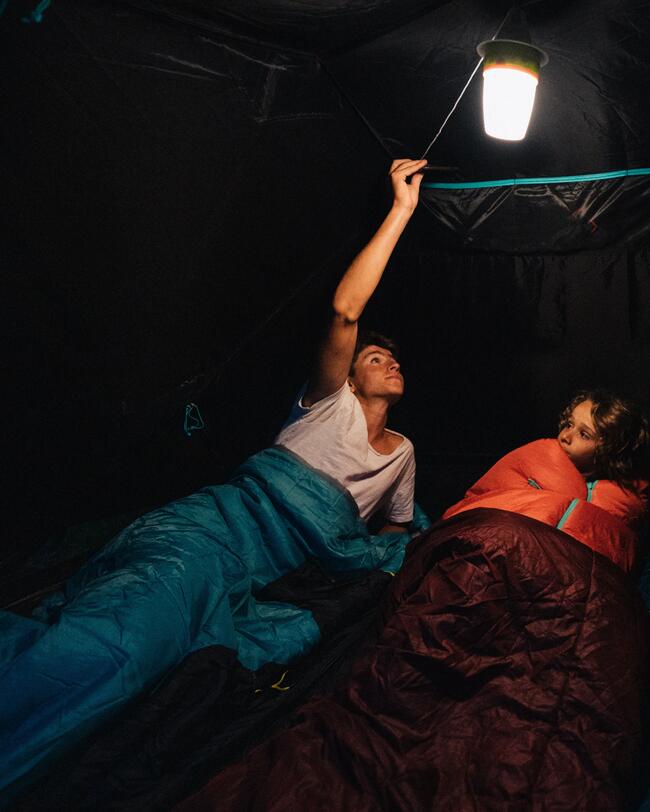

Darkness on demand

Stay cool, sleep well, and enjoy 99% darkness day or night with our flysheet, air vents, and patented blackout fabric.

Room for two active campers

Escape to the outdoors with our 2-person tent, featuring one bedroom and space to sit and debrief your day.

Camping Made Simple

Enjoy flexibility with its free-standing dome structure - relocate easily for the perfect views even after pitching.

Darkness on demand

Stay cool, sleep well, and enjoy 99% darkness day or night with our flysheet, air vents, and patented blackout fabric.

Room for two active campers

Escape to the outdoors with our 2-person tent, featuring one bedroom and space to sit and debrief your day.

Camping Made Simple

Enjoy flexibility with its free-standing dome structure - relocate easily for the perfect views even after pitching.

Darkness on demand

Stay cool, sleep well, and enjoy 99% darkness day or night with our flysheet, air vents, and patented blackout fabric.

Room for two active campers

Escape to the outdoors with our 2-person tent, featuring one bedroom and space to sit and debrief your day.